Common Mistakes to Avoid When Laser Cutting and Engraving Acrylic – 2024 Guide

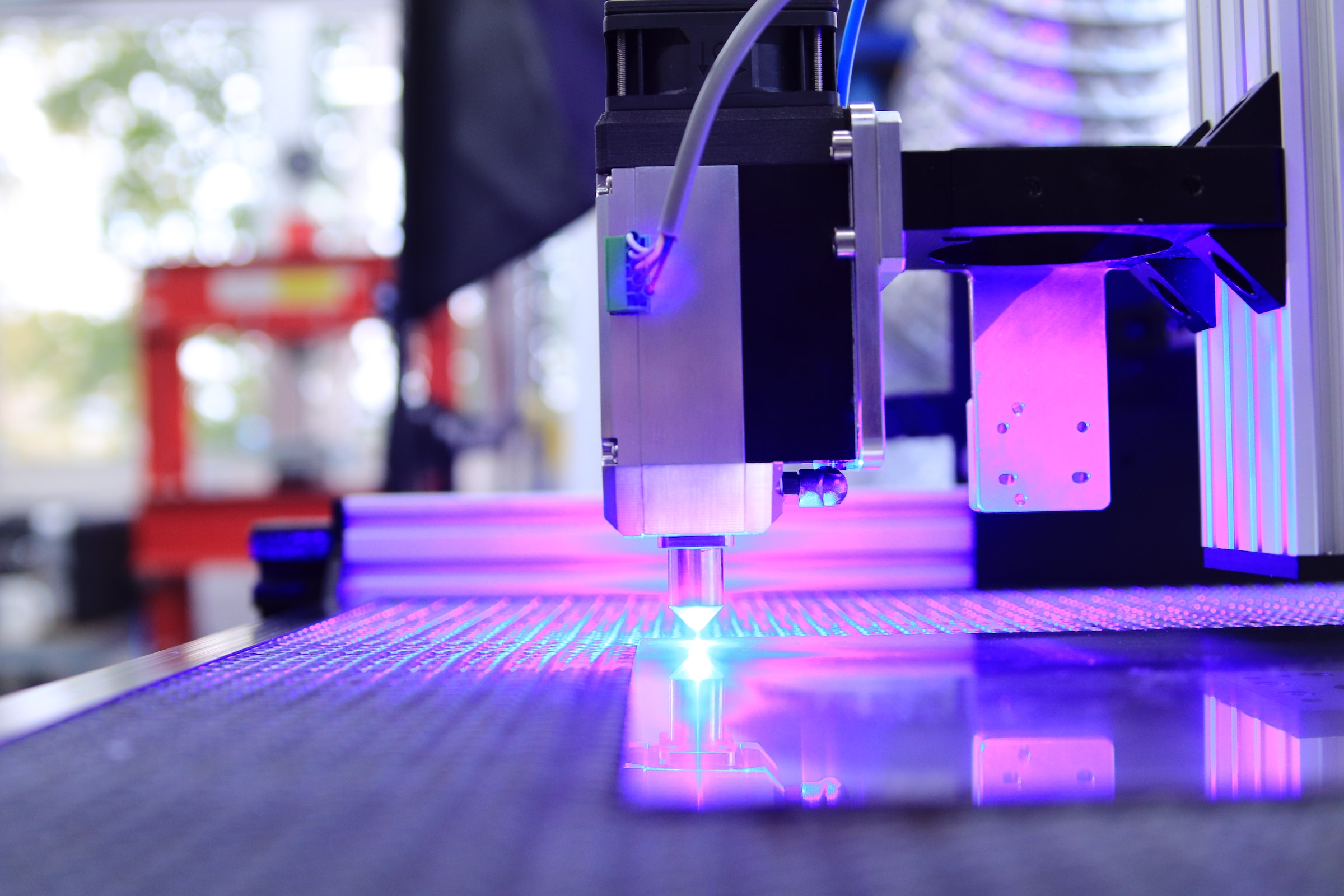

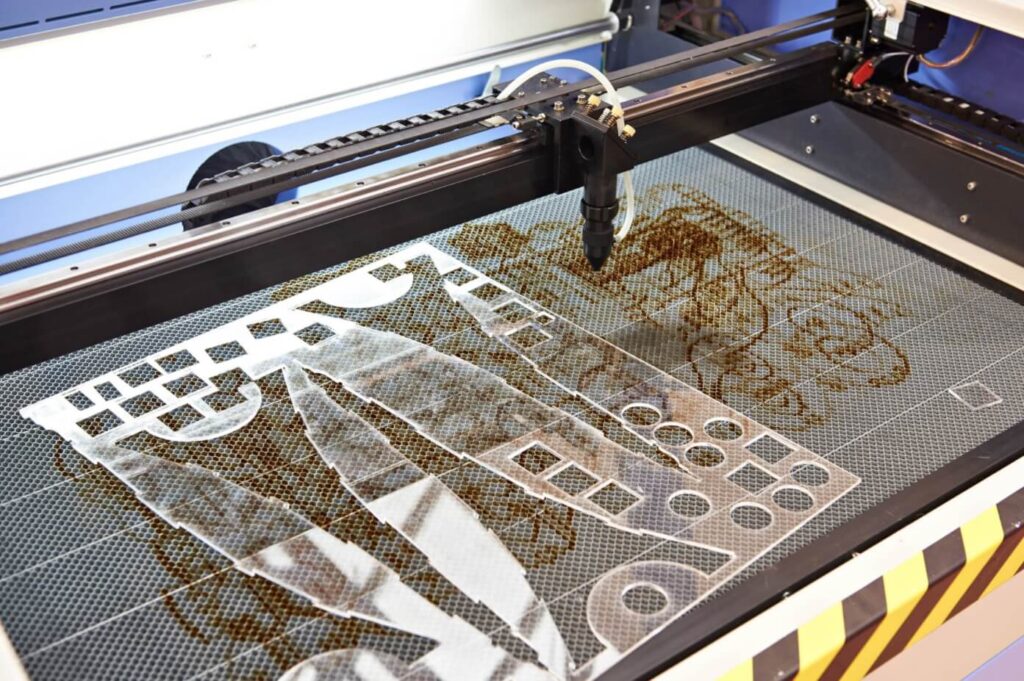

Acrylic is a versatile material that is used for a wide range of applications, including signage, displays, and artwork. When it comes to creating precise and intricate designs on it, laser cutting and engraving are the go-to methods. However, as with any process, there are common mistakes that can be made when laser cutting and engraving acrylic. In this guide, we will discuss some of these mistakes and how to avoid them.

1. Not Using the Right Settings

One of the most common mistakes people make when laser cutting and engraving acrylic is not using the right settings. This can result in incomplete cuts, burns, or melting of the material. It is essential to choose the correct laser power, speed, and frequency for the specific type of acrylic you are using. Different types have different melting and cutting points, so it is important to experiment with various settings until you find the right combination that produces the desired results.

2. Not Cleaning the Acrylic

Another mistake that can be made is not cleaning the material before starting the process. Any dirt, dust, or debris on the surface of the acrylic can interfere with the laser’s ability to cut or engrave accurately. Before starting, it is crucial to clean it with a lint-free cloth and a gentle cleaning solution to remove any contaminants.

3. Not Using the Right Type of Acrylic

Using the wrong type of acrylic is another common mistake when laser cutting and engraving. Not all types are created equal, and some are better suited for laser cutting and engraving than others. For example, cast acrylic is the best option for laser cutting and engraving because it produces a smooth, clear edge when cut. Extruded one, on the other hand, can result in a cloudy, frosted edge when cut. It is important to choose the right type of it for your specific project to ensure the best results.

4. Not Securing the Acrylic Properly

When laser cutting and engraving acrylic, it is crucial to secure the material properly to prevent it from moving during the process. If the acrylic moves even slightly, it can result in uneven cuts or engraving. To prevent this, it is recommended to use clamps or tape to secure it firmly to the laser bed.

5. Using the Wrong Type of Vector Graphics

Vector graphics are essential for laser cutting and engraving, as they provide the laser with the instructions it needs to create the design. However, using the wrong type of vector graphics can lead to inaccurate cuts or engraving. It is important to use vector graphics that are designed specifically for laser cutting and engraving. These graphics will have a specific set of instructions that are optimized for the laser-cutting process, ensuring accurate results.

6. Not Running Test Cuts

Before starting a large project, it is essential to run test cuts to ensure that the settings and design are correct. This can help prevent wasted materials and ensure the final product meets your expectations. Running test cuts is especially important when working with a new type of acrylic or a design that is particularly intricate.

7. Not Wearing Protective Gear

Laser cutting and engraving can produce harmful fumes and particles, so it is crucial to wear protective gear to prevent any health risks. This includes a mask or respirator, safety goggles, and gloves. It is also recommended to work in a well-ventilated area to reduce exposure to harmful particles.

In conclusion, laser cutting and engraving acrylic can produce stunning results, but it is important to avoid common mistakes to achieve the best outcome. With these tips in mind, you can create precise and intricate designs on acrylic that are sure to impress. Remember, taking the time to properly prepare and execute your laser cutting and engraving project will result in a finished product that is both visually appealing and high-quality.