Demystifying FR-4: An In-depth Guide to Its Properties and Benefits for PCBs

When it comes to printed circuit boards (PCBs), one term that you are likely to come across is FR-4. But what exactly is FR-4, and why is it so important in the world of PCB manufacturing? In this in-depth guide, we will demystify FR-4, exploring its properties and highlighting the benefits it brings to PCBs.

FR-4 is a widely used material in the production of PCBs. It is a glass-reinforced epoxy laminate that exhibits excellent electrical insulation properties, making it an ideal choice for circuit board substrates. But what sets FR-4 apart from other materials? Let’s delve deeper into its properties to find out.

Electrical Insulation

FR-4 is renowned for its exceptional electrical insulation properties. It has a high dielectric strength, meaning it can withstand high voltages without conducting electricity. This characteristic is crucial for preventing short circuits and ensuring the integrity of the circuitry.

Thermal Stability

PCBs often operate in demanding environments that subject them to temperature extremes. FR-4 offers excellent thermal stability, allowing it to withstand elevated temperatures without losing its structural integrity. This property is particularly important in applications where PCBs are exposed to high-power components or undergo soldering processes.

Mechanical Strength

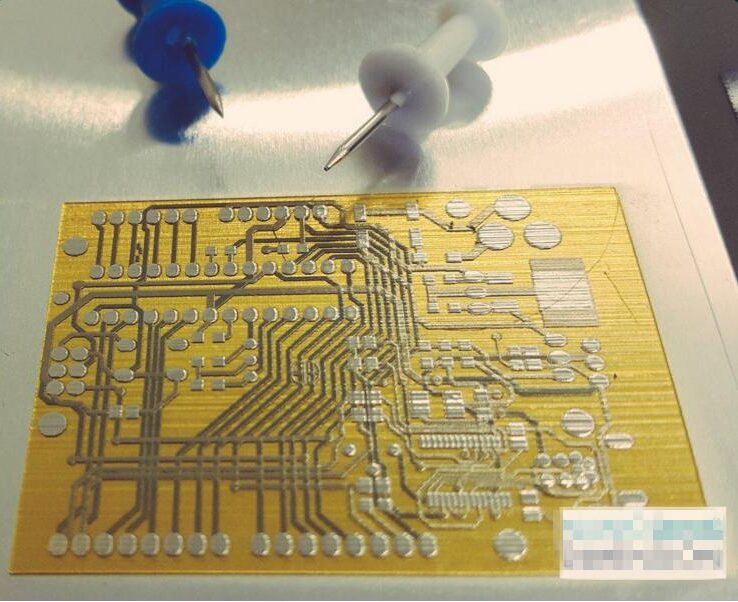

FR-4 is known for its robustness and mechanical strength. The glass reinforcement provides rigidity and stability to the laminate, making it highly resistant to bending, twisting, and impact. This strength ensures that the PCB can withstand the rigors of assembly, installation, and operation.

Flame Retardancy

Safety is a paramount concern in electronics, especially when it comes to fire hazards. FR-4 is inherently flame retardant, meaning it has the ability to resist combustion and limit the spread of flames. This property significantly reduces the risk of fire and enhances the overall safety of electronic devices.

Chemical Resistance

PCBs often come into contact with various chemicals during their lifespan. FR-4 exhibits excellent resistance to chemicals such as acids, bases, and solvents. This chemical resistance ensures that the PCB remains unaffected by external factors and maintains its functionality over time.

Now that we understand the key properties of FR-4, let’s explore the benefits it brings to PCB manufacturing.

Cost-effectiveness

FR-4 is a cost-effective material, making it the go-to choice for many PCB manufacturers. Its availability and widespread use contribute to its affordability, making it suitable for both small-scale and large-scale production.

Versatility

FR-4 is highly versatile and can be used in a wide range of applications. Whether it’s consumer electronics, automotive systems, or industrial equipment, FR-4 can adapt to various requirements and specifications, making it a versatile material for PCB fabrication.

Design Flexibility

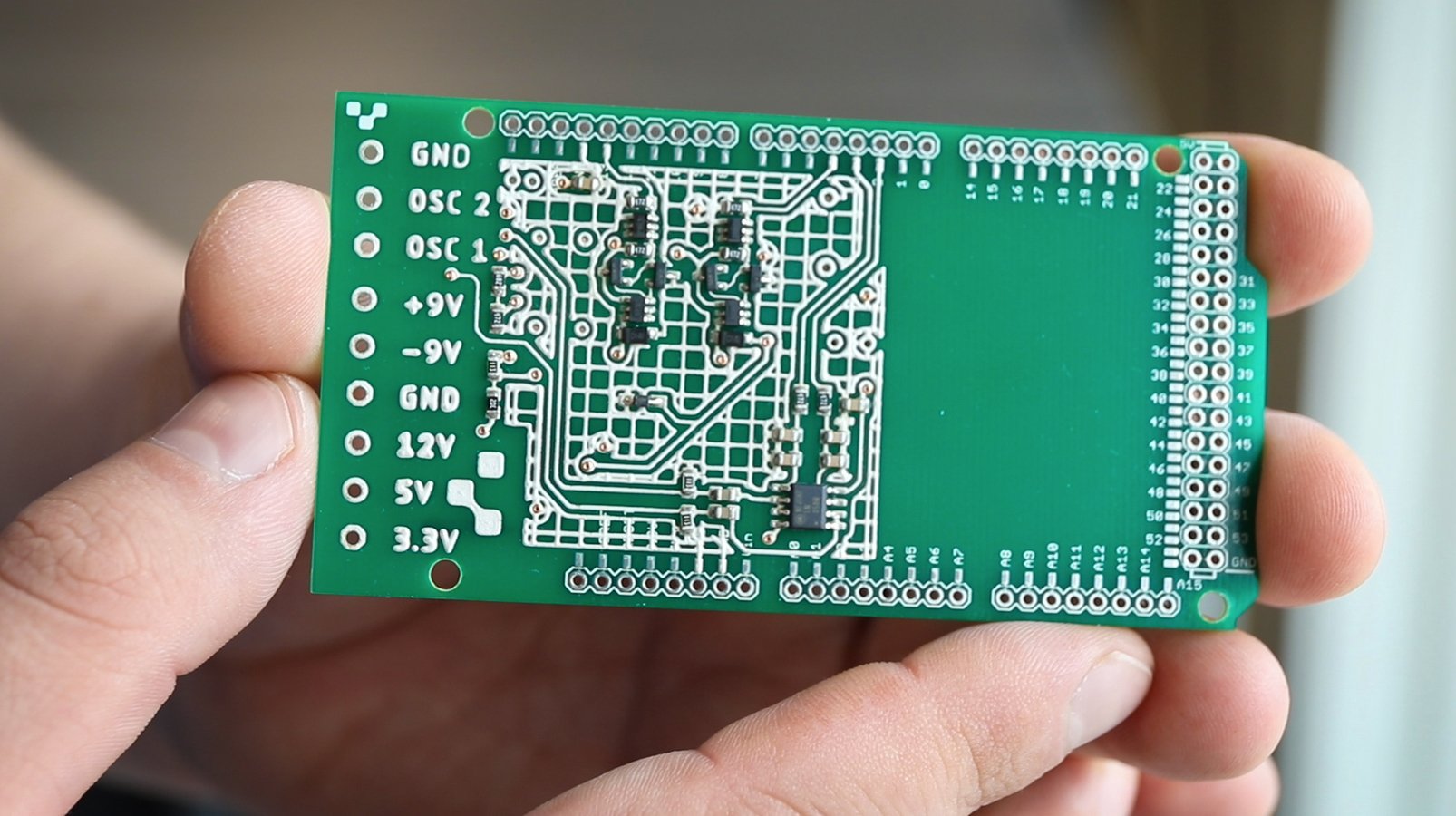

FR-4 allows for intricate and complex PCB designs. Its high dimensional stability and excellent dielectric properties enable the creation of fine traces, small vias, and densely packed components. This design flexibility is essential for modern electronic devices that demand compactness and high functionality.

Reliability

FR-4 is a tried and tested material known for its reliability. Its excellent electrical insulation and mechanical strength contribute to the long-term performance and durability of PCBs. This reliability is crucial in mission-critical applications where failure is not an option.

So, the next time you hold a sophisticated electronic device in your hands, marvel at the intricate circuitry that lies within, and remember that FR-4 played a vital role in bringing it to life. Behind the scenes, this unassuming material silently empowers our technological advancements, ensuring the reliable and efficient functioning of the electronic marvels that shape our world.