Can CNC Machining Be Used For Rapid Prototyping Purposes?

Time is of the essence while producing products. Businesses are constantly seeking methods to sell their products more quickly without sacrificing quality. Rapid prototyping can be a game-changer to make the production process smooth and less time-consuming. The use of prototyping techniques like injection moulding and 3D printing is widely seen throughout business industries.

However, due to the production of excellent prototypes with amazing precision and speed today, CNC machining has grown in popularity. The process of developing and testing new designs is being revolutionised. For those seeking precision CNC machining services, CNC machining offers an ideal solution to bring their innovative ideas to life.

The Role Of CNC Machining In Rapid Prototyping

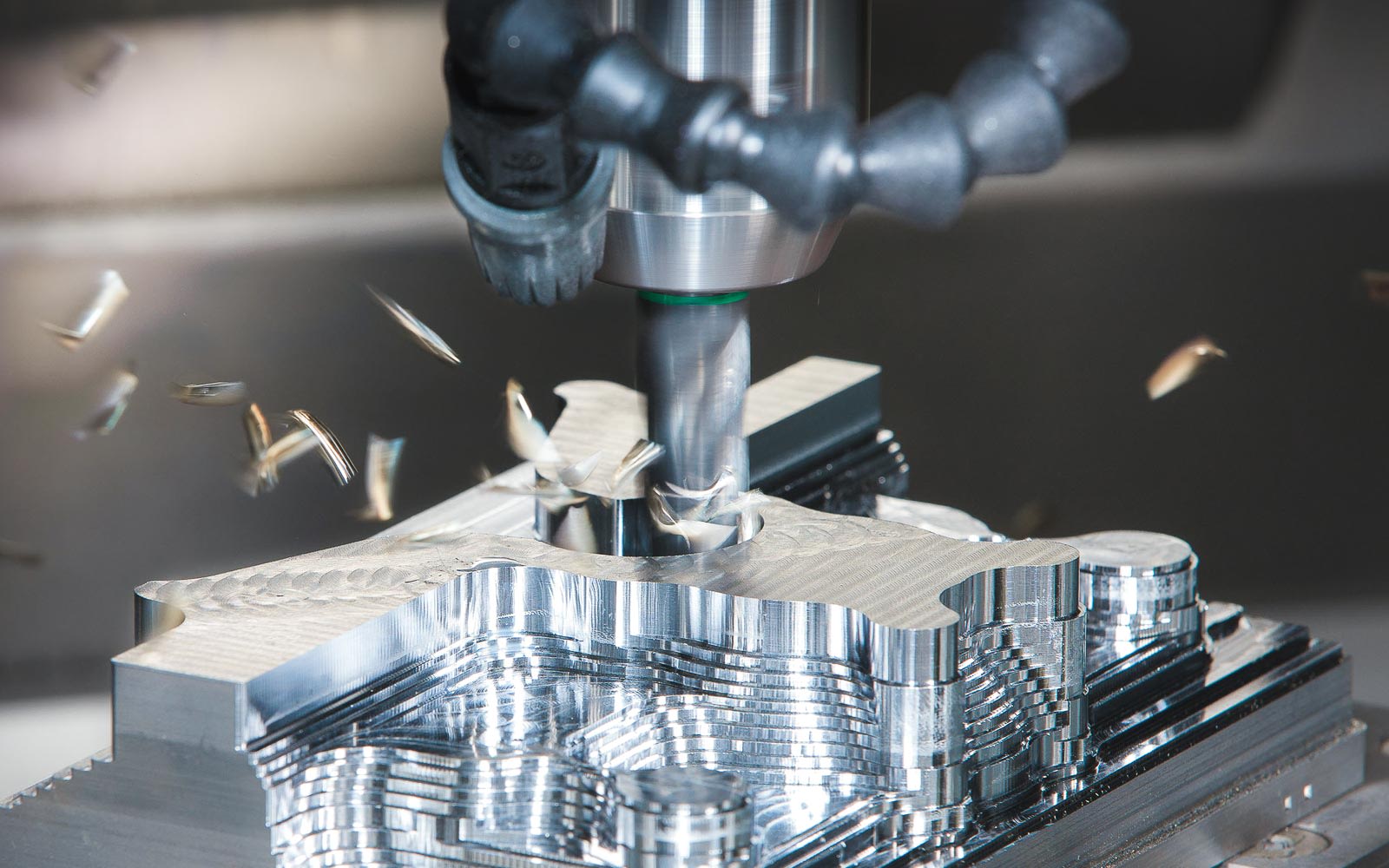

Computer numerical control (CNC) machining is a manufacturing method that uses pre-programmed computer software to direct the movement of tools and machines. It makes use of subtractive manufacturing, in which different materials are used to produce the required form or part.

In the production process, machine tools including mills, lathes, and routers are controlled and operated by computer systems. Rapid prototyping is one of the many applications for which CNC machines are suited since they can manufacture sophisticated designs with precise designs. This technique is favoured by many manufacturing industries because it enables accurate and effective material shaping.

In comparison to traditional manual machining, CNC machining has a number of benefits. Organisations can automate production processes resulting in lower human errors and providing reliable, accurate output. Besides, CNC machines can run continuously, considerably raising output rates. These advantages have elevated this manufacturing process to a pillar of modern industry.

Reasons CNC Machining Is Effective For Rapid Prototyping Purposes

When it comes to rapid prototyping, business industries are regularly adopting creative methods to bring their ideas to life swiftly and efficiently. CNC machining has emerged as a powerful and reliable solution for rapid prototyping purposes. Here are a few reasons this manufacturing process can be effective for your business’s rapid prototyping needs.

1. Precision and Accuracy

The unmatched accuracy that CNC machining provides is one of the main benefits of using technology for rapid prototyping. CNC machines precisely replicate digital drawings, guaranteeing that the prototype produced is a perfect representation of the desired final product.

Engineering and design professionals may confidently test and analyse their prototypes because of their ability to attain precision within fractions of a millimetre. This accuracy reduces mistakes and enables revisions early in the design phase, which saves money and shortens the manufacturing cycle.

2. Quick Manufacturing Process

Rapid prototype relies heavily on speed, and CNC machining excels at providing quick turnaround times for low-volume productions. CNC machines can create prototypes in a couple of days, as opposed to traditional manufacturing processes, which might take weeks or months.

Companies may shorten their manufacturing cycles, react quickly to market needs, and gain a competitive edge with the use of this quick manufacturing for short production cycles.

3. Cost-Effective

Rapid prototyping can be cost-effective by using CNC machining. Although certain conventional methods may need a greater initial setup cost, the absence of expensive tools and the decrease in physical labour lead to long-term cost reductions.

Additionally, CNC machining is an economically sensible option for both major companies and small organisations due to the ease with which any alterations or design changes may be rapidly implemented without incurring substantial costs.

4. Easy To Make Complex Prototypes

Making complicated and complex geometries is common in rapid prototyping. CNC machines excel at this task due to their amazing accuracy in material manipulation and shaping. No design is too complicated to be translated into a tangible prototype, whether it has 3D curves, complex patterns, or minute details.

5. Reproducibility And Consistency

Another outstanding feature is the capability of CNC machining for rapid prototyping to produce several identical prototypes at the same time. Once the design and settings are complete, the CNC machine can create a large number of identical prototypes.

It ensures that each prototype is reliable and suitable for testing and evaluation. When you are conducting user trials and batch testing and require precise input before moving into full-scale production, this is extremely critical.

6. Improved Automation

It’s amazing how little pushing and probing throughout manufacturing is required making the manufacturing process completely automated. Simply program the parameters and design, and the machine will continue to produce prototypes on its own. The manufacturers may now focus on more crucial tasks that are significant to the production process. Besides, the automated process helps reduce human mistakes, resulting in a highly accurate and dependable final product.

Drawbacks Of CNC Machining For Rapid Prototyping

The use of CNC machining for rapid prototyping needs in business industries has benefitted in multiple ways ensuring the effectiveness of the manufacturing process. However, irrespective of the reasons to use this process for rapid prototyping, there are a few drawbacks that you must be aware of, such as:

1. Expensive Setup Costs

The greater initial setup expense is one of the major difficulties. Contrary to 3D printing, which may be quite affordable for smaller projects, CNC machining needs specialised equipment and programming, which can raise the cost overall.

2. Limited Feasibility

The lengthier lead periods for large-scale production are another drawback. Even though CNC machining is excellent for creating working prototypes, it might not be the most effective choice for high-volume manufacturing. Due to long manufacturing cycles, the procedure might not be as economically feasible for making a substantial quantity of products.

3. Additional Post-Processing

To obtain the appropriate surface quality, further post-processing may be necessary for some designs. While CNC machines may produce prototypes that are quite precise, getting a smooth surface may need additional finishing procedures, which extends the process’s duration and increases its cost.

Final Thoughts

CNC machining has emerged as a reliable tool for usage in rapid prototyping because it can generate exceptionally precise, functional, and diversified prototypes in a short amount of time. It benefits organisations to accelerate their product development processes.

Although CNC machining does not entirely replace additive manufacturing technologies like 3D printing, it can provide a wide range of possibilities for various prototype requirements. As technology advances, business organisations expect more efficient and environmentally friendly CNC machining processes, further revolutionising the quick prototype business.