5 Ways Technology Has Improved the Quality of Heat Resistant Materials

Technology has improved and affected every industry in the world, and our lives are better and safer when we implement the newest products, devices, and equipment. Heat-resistant materials are used in pretty much every industry, and they are a huge part of every manufacturing process. These products are utilized for our human crew, as well as for protecting our equipment from meting and getting damaged from heat. However, all of these materials have their limits, and when we stick only to the basis, we don’t get the necessary protection. Luckily, modern technology has affected this field greatly, and here we will tell you how it has improved the quality of heat resistant materials.

1. Better cutting processes

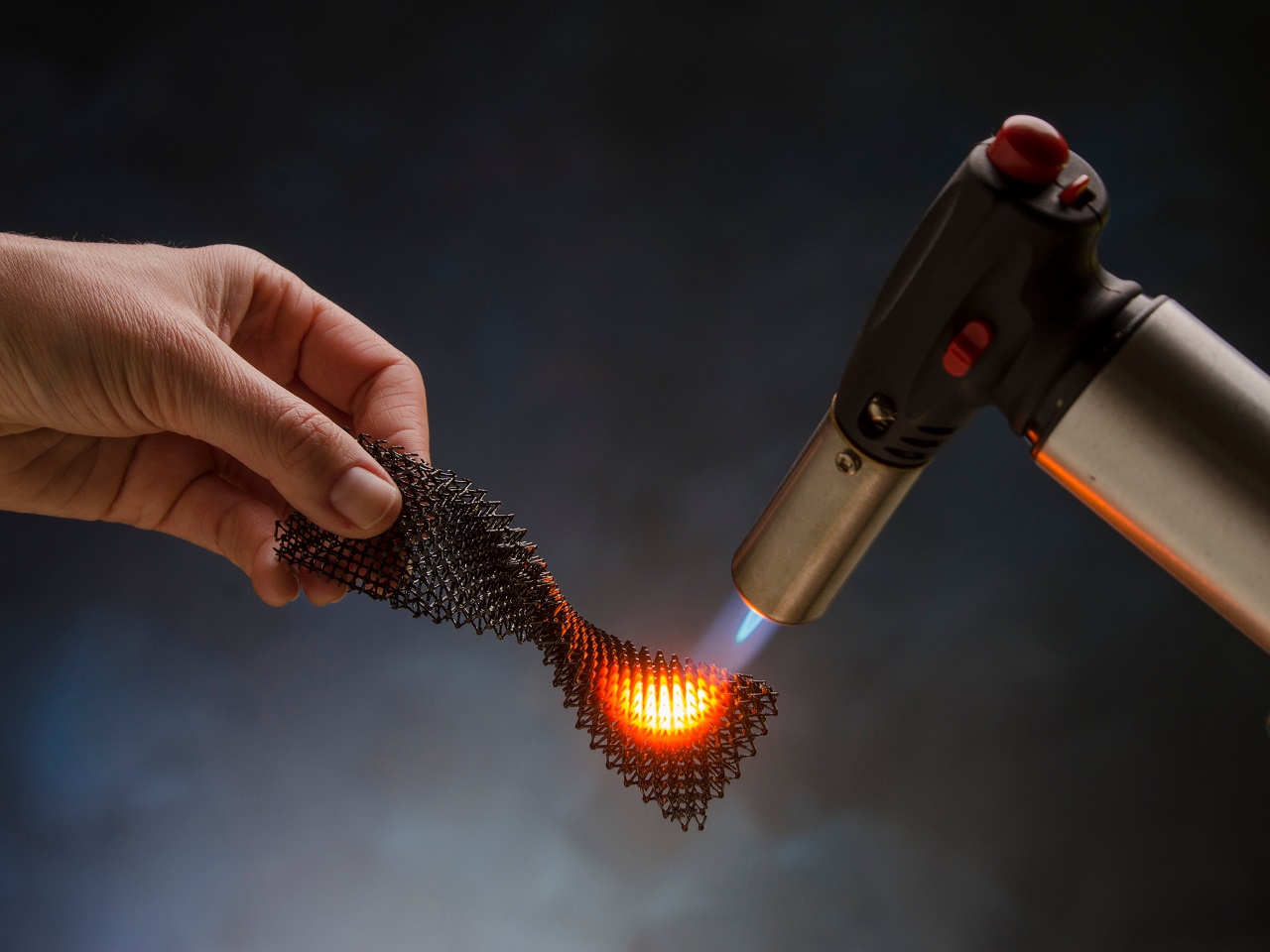

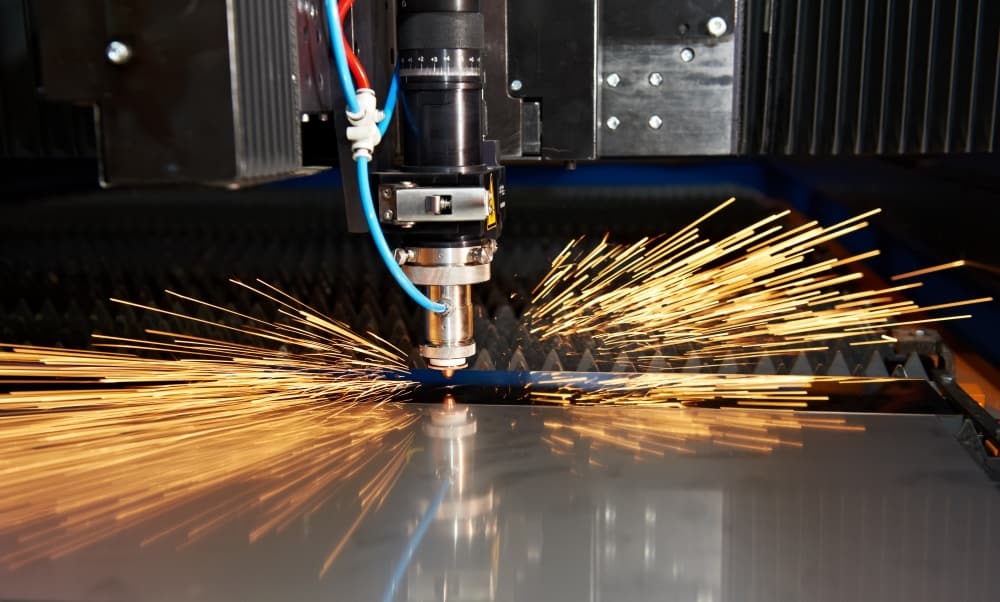

Manufacturing things and improving them can help us protect our devices, personnel, and it can help us save a lot of costs, but at one point, we need to start implementing those materials and we need to custom cut and fabricate them together.

In the past, the biggest problem arose when things needed to be cut and sewn together, and in many cases, the materials that were available for us were not able to serve their purpose because they got damaged during the cutting or fabrication processes. Well, thanks to modern technology, this is an issue of the past, and now, special devices are used to cut the materials that we work with without melting or damaging them.

The process is done using special equipment that protects the fabric as well as its surroundings and is still able to make the cut. All of these processes are automated, and human workers need to only monitor the process without putting their safety or health at risk.

2. Custom manufacturing and fabrication

As we mentioned before, technology has been used to create new materials, but it is also utilized to help improve the ones that we already have, and to make sure that the materials we work with are not going to get damaged during the manufacturing process.

With custom fabrication, you can protect your products, equipment, and workers from fires, chemical hazards, as well as natural gas and manmade heat. According to ADL Insulflex, with the implementation of the latest technologies, we are able to focus on all the small details without leaving room for failure, and that can be noticed in every aspect of our lives.

Things that have been created and improved include heat protection blankets, protection systems for heavy-duty workers including plasma gouging, welding, and grinding, fire blankets for the automotive and aerospace industry, and specialized blankets for not only the workers but also for the machines and equipment.

3. Creating new materials

Bettering the things that we already have can only go so far, and no matter what types of technologies we implement, there are always going to be limits. However, that is not the case when we create something new from scratch, and thanks to the devices and equipment we now have, researchers have been able to create new materials that are better and more resilient than ever.

Hafnium carbonitride is a new material that was developed just for this purpose and its melting point is north of 4000 degrees Celsius. To make a comparison, the lava that we find in volcanos reaches less than 1300 degrees Celsius, whereas the sun’s surface is about 5500 degrees Celsius. This means that the material that was manufactured will be utilized in any missions that we choose to have in space, and it is resilient to almost everything that can be found on earth. This discovery has made things a lot simpler and it has provided additional protection against different chemicals and materials.

4. Improved overall resilience

When we think about bettering our experience with materials, we want to pay attention to more than just heat resilience. Well, modern technology and innovative solutions have allowed researchers to focus on more than making the products be able to withstand higher temperatures, and they have also improved their other physical properties.

Most of the materials that are heat resilient are also water and dustproof, and they don’t get damaged when they are subjected even to extremely low temperatures. Since some can be used for creating space shuttles, they are also resilient to anything that could damage when they leave the planet and when they come back. This has made things far better and simpler, and it has helped us save hundreds of thousands and even millions of dollars.

5. Better analysis and solutions

The way things are improved is by trial, analysis, and error. When we just assume things and make changes, there is no way for us to get perfect results or solutions. Modern technology has allowed scientists to do a deep analysis of the materials and it has allowed them to closely monitor everything that is happening.

This way we can see what type of heat affects the products and what is their exact melting point. It also shows the way the heat is distributed and what can be done to avoid or prevent melting or damage.

When the needed research is done, we get innovative solutions, or we can just know what is the problem that we are trying to tackle. With the help of better machines and improved software, we are able to do constant monitoring and with that, better understand the results that we are getting.

These are some of the ways that technology has improved the quality of heat resistant materials, and it is expected for things to continue going in the right direction. All of these processes are extremely complex and difficult to understand, so if you are interested in delving deeper into any or all of them, it is best if you talk to a person who is closely involved in the research process. We are lucky to live in a time when everything is advancing extremely fast, and we will probably witness a lot more discoveries and successes not only with these materials but also in everything else they are implemented in.