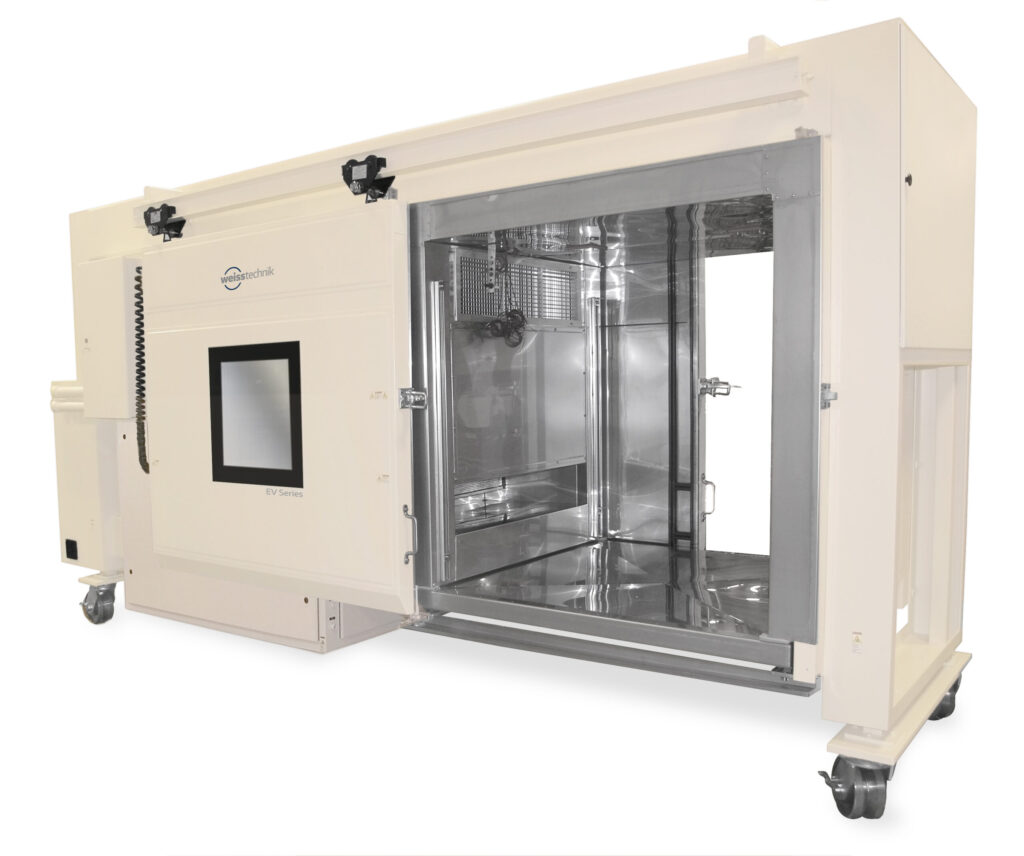

When it comes to ensuring the reliability and durability of products, one crucial aspect is understanding how they respond to mechanical stress. Vibration test chamber testing is a powerful tool that allows engineers and manufacturers to simulate real-world conditions and identify potential weaknesses or flaws in their designs. In this blog post, we will delve into the fascinating world of this testing, exploring its significance, and discussing key considerations to master this process.

Understanding Mechanical Stress

Mechanical stress refers to the forces that act upon a material or product, causing it to deform or fail. In various industries such as automotive, aerospace, electronics, and many more, products must endure constant vibrations and shocks during their operational life. Vibration test chamber helps assess the structural integrity and performance of these products under such stressful conditions.

Importance of Vibration Test Chamber Testing

Simulating Real-World Conditions

Vibration test chamber replicates the vibrational forces and frequencies that a product may experience during its intended use. By subjecting the product to controlled vibrations, engineers can identify potential weaknesses and areas for improvement. It allows for a more accurate evaluation of product performance and reliability under realistic conditions.

Enhancing Product Reliability

By identifying design flaws or weaknesses early in the development process, a vibration test chamber helps manufacturers improve product reliability. It enables them to make necessary modifications to enhance the structural integrity and durability of their products, ensuring they can withstand the rigors of real-world usage. Ultimately, this leads to higher customer satisfaction and lower warranty claims.

Key Considerations for Vibration Test Chamber Testing

Test Planning and Preparation

Effective planning is essential to ensure accurate and meaningful results. Before conducting any vibration test, it is crucial to define the specific objectives, including the desired vibration profile, its duration, and measurement parameters. Proper preparation involves selecting suitable instrumentation, ensuring proper fixturing and securing of the test specimen, and validating its setup to minimize unwanted variables.

Understanding Vibration Profiles

Vibration profiles define the amplitude, frequency, and duration of the applied vibrations. It is crucial to understand the specific vibration profile that accurately represents the intended use environment. Different industries may have unique standards or specifications for vibration testing, and compliance with these guidelines is essential. Understanding the expected vibration profiles allows for a more targeted approach to identifying potential failure modes and evaluating product performance.

Fixture Design and Mounting

Proper fixture design and mounting are critical for accurate and reliable test results. Fixtures should be designed to simulate the real-world mounting conditions of the product being controlled. This includes considering factors such as the mounting orientation, clamping forces, and potential resonant frequencies. A well-designed fixture ensures that the product is securely held in place and that the vibrations are transmitted effectively to the test specimen.

Data Acquisition and Analysis

Accurate data acquisition and analysis are essential for interpreting the results and making informed decisions. High-quality sensors and data acquisition systems should be used to capture the necessary measurements during the test. Post-test analysis involves examining the collected data, identifying any anomalies or failure modes, and determining the root causes. Advanced data analysis techniques, such as frequency analysis or time waveform analysis, can provide valuable insights into product behavior.

Conclusion

So, the next time you encounter a well-engineered vehicle, a sturdy electronic device, or a resilient aerospace component, remember that behind its excellence lies a series of vibration test chamber tests, enabling its creators to conquer mechanical stress and achieve mastery in their field.