Designing With Aluminum Profiles: Tips for Optimizing Linear Motion Solutions

Aluminum is a material used for various purposes and in various industries. One of the major reasons why it is used so widely is the flexibility it provides. With that in mind, you can see it as a substitute for many materials that do not offer the much-needed flexibility. Of course, utilizing methods that will help with the processing procedure is essential. As you can presume, only experienced professionals can do it properly.

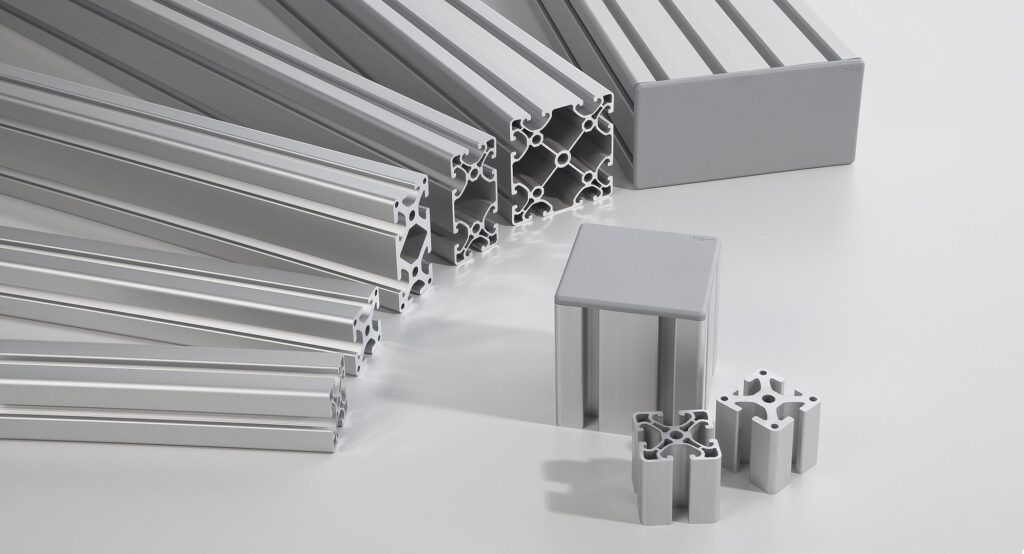

There is not only one solution that can serve as an answer to every question. Think about it; different processes have different needs. Therefore, expecting that everything you do can help achieve the best linear motion of the best quality is unreasonable. For example, when you compare aluminum with titanium and steel, you will see that aluminum offers a feature others do not, flexibility. Sometimes, conducting them in complex shapes is necessary.

As we have said, understanding the proper way of designing aluminum profiles does not work without the necessary experience. Today, we want to discuss some tips to help you optimize linear motion solutions. So, without further ado, let us look at the most important tips.

Specifying Metal Thickness

When you are about to process the material to get the shape you want, you should know there are potential pitfalls. Therefore, it is crucial to assess these and find a way to prevent them from happening. By doing that, the process will ensure that keeping sufficient metal thickness around the profile you are interested in getting at the end of the process. The thickness is crucial for meeting the structural requirements.

The shapes you get should be resilient enough to sustain all the influences that might occur down the road. But, at the same time, they need to remain functional. Otherwise, there is a potential problem of it experiencing issues that can damage the structural quality of the device. Another thing you can expect to achieve with enough thickness is flexibility. Even if some adjustments are made, the piece should return to its original shape.

When the thickness is too thin, this becomes impossible. The reason is the low level of protection the piece will have. With that in mind, it is essential to prevent asymmetrical profiles, which are not as resilient as you need them to be. Therefore, the one behind the project should specify the metal thickness by calculating all the major elements, resulting in much higher resilience.

Preparing the Material

Aluminum, like any other material out there, requires preparation before you can expect any process to be as accurate as possible. Thankfully, there are numerous ways you can do so. The thing is to know the material and the machinery that will help you achieve the right level of accuracy. Fortunately, you can rent these machines and use them for this procedure. You can also hire professionals to help you access the possibilities of the material.

Thankfully, you can buy aluminum extrusions in many different ways. Still, the option you decide on when it comes to the capabilities of cutting your machines and material will depend solely on the machinery you have and how these machines can handle the materials. That is why you need to properly understand these processes and how to prepare the material for the design process.

You will not need to worry about these things if you already have the proper machinery. But, on the other side, it is exceptionally hard to conduct this process. Fortunately, we can conduct these processes more easily than ever.

Designing Surface Finish

The next aspect we want to discuss is the importance of designing the surface finish. When you think about that, this makes perfect sense for numerous reasons. For example, your device may work solely on one surface finish. By creating the framework where this will work properly, you will have a chance to find the blueprint to make things work as best as you want them to. The designing process is necessary in this case.

If you have an engineer on your team, those making sketches that will specify the aspect of providing the right framework of the surface will be easier. However, if this is not the case, we advise you to recruit a professional who will help you achieve the right level of accuracy and experience. Being accurate is extremely important in aluminum surface designing procedures. Otherwise, you can come across numerous problems.

The damage to the surface, which can arise for countless reasons, can cause many problems down the road. The thickness of the material can play a massive role in these changes. That is why it is essential to consider that before the designing process. By minimizing the marking of exposed surfaces, you will avoid many potential problems. You can achieve this by utilizing the design properly.

Problems with Over-Dimensioning

Lastly, we want to talk about the problems regarding over-dimensioning. Knowing the right dimensions for the part you will design with aluminum profiles is essential. Otherwise, you will encounter many problems, such as these parts not fitting the others, without even going into the design details. Of course, the problem with this element is that it leads to wasting money, which nobody wants.

If you know the right measures, you will have no problems finding the part that will fit your overall structure. So, you can always choose the right parts, such as an aliminium profile 60×60 from company Tuli. Naturally, this requires the measuring process to take part before you even start the designing process. While it may seem straightforward initially, you will quickly see that it is not as simple as it may look.

The Bottom Line

As you can see, we are not talking about an easy procedure. In fact, it requires a lot of preparation and knowledge before you can conduct it properly. In this article of ours, you can look at tips that will prove essential. We are certain you will find this insight to be of massive help down the road.