Behind the Medal: The Creative and Manufacturing Process

When we see a medal adorning the chest of an accomplished individual, we often overlook the intricate journey it took to come into existence.

Medals represent not only achievement but also the creativity, craftsmanship, and dedication of the people behind their creation.

This article delves into the fascinating world of medal design and manufacturing, uncovering the meticulous process that turns an idea into a tangible symbol of excellence.

Conceptualization and Design

The first step in creating an award medal is conceptualization. Whether it’s to honor sporting achievements, commemorate historical events, or celebrate academic accomplishments, a clear concept is vital. The design must reflect the essence of the achievement it symbolizes.

Designers work closely with clients or organizations to understand their vision, often considering factors like size, shape, and symbolism.

Sketching and Digital Rendering

Once the concept is defined, designers transition to sketching and digital rendering. Using advanced design software, they translate ideas into visual representations. This stage allows for fine-tuning details, experimenting with different design elements, and ensuring that the design aligns with the intended message.

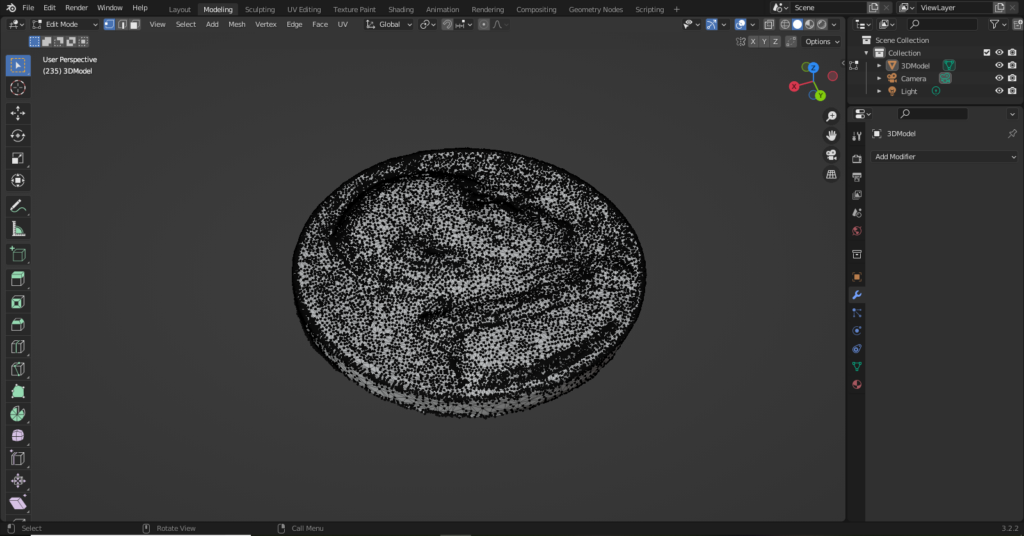

Sculpting and Model Creation

After finalizing the digital design, the next step is bringing the design to life in three dimensions. Skilled sculptors meticulously hand-carve or digitally sculpt the medal’s model. This model serves as the prototype from which the final medal will be created.

Mold Creation

Using the sculpted model, a mold is created. This mold is the foundation for mass production. It is crafted with precision to capture every intricate detail of the original design. The mold is often made from materials like silicone, rubber, or metal alloys, depending on the production method.

Material Selection and Production

Medals can be crafted from various materials, including metal alloys like bronze, silver, and gold. The choice of material impacts the medal’s appearance, weight, and durability. The selected material is melted down and poured into the mold. Once cooled, the medal is removed and carefully inspected for quality.

Finishing Touches

The raw cast medal undergoes several finishing processes to achieve its final appearance. These processes include polishing, plating (if applicable), and applying any enamel or coloring. The goal is to enhance the design’s details and make the medal visually appealing.

Packaging and Presentation

The final step involves packaging and presenting the medal. This includes designing elegant presentation cases that not only protect the medal but also complement its significance. The packaging often incorporates elements that align with the event or achievement being celebrated.

Conclusion

Behind every medal lies an intricate and dedicated process that combines creativity, skilled craftsmanship, and advanced manufacturing techniques. From the initial concept to the final presentation, each step plays a pivotal role in transforming an idea into a tangible emblem of accomplishment.

The next time you see a medal proudly displayed, take a moment to appreciate the journey it undertook – from the mind of a designer to the hands of skilled artisans – before finding its rightful place as a symbol of excellence.

Check out what medals were given to whom at the Tokyo 2024 Summer Olympics and learn something you might have not known already.