Lipo-Battery Welding Versus Alternatives: Which Is Right for You?

When it comes to building or repairing battery packs, one of the critical decisions you’ll face is how to connect the individual cells together. Lipo-battery welding is a popular method, but there are alternatives to consider. In this article, we’ll explore the pros and cons of lipo-battery welding compared to other techniques to help you make an informed choice.

Lipo-Battery Welding: The Basics

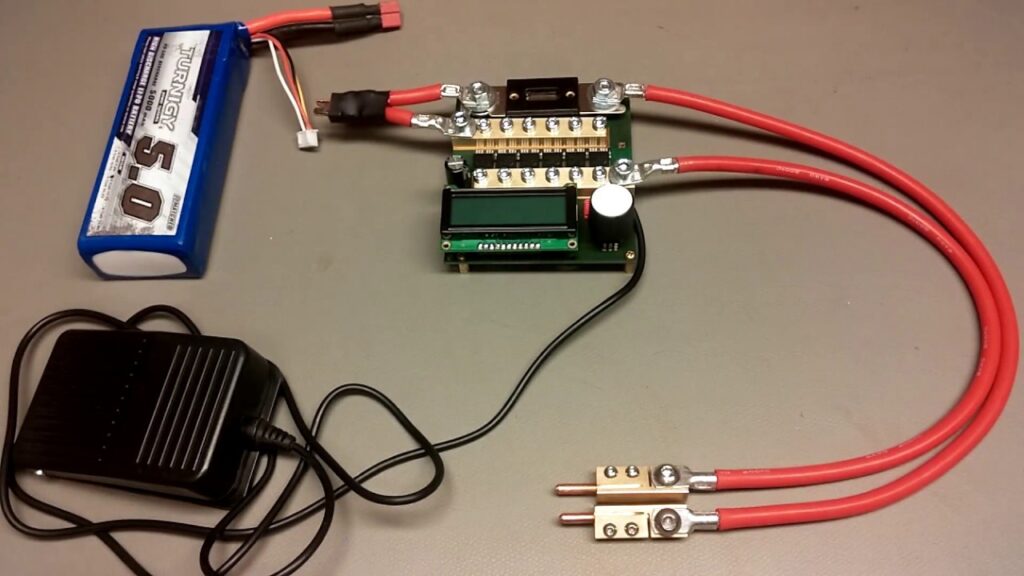

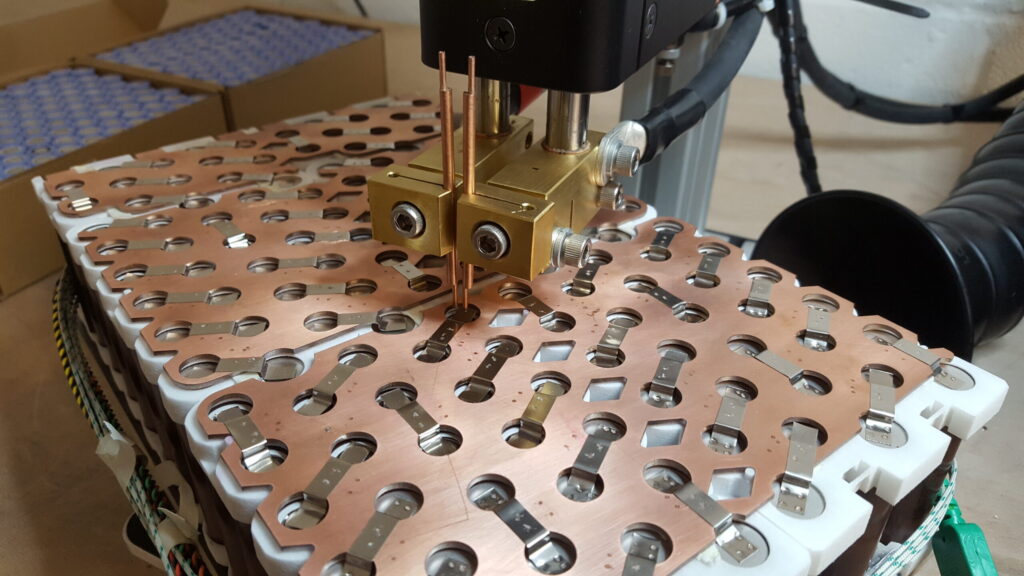

Lipo-battery welding, also known as spot welding, involves using a specialized welder to create tiny electrical sparks that melt the nickel strips onto the battery cells. This method is widely used in the manufacturing and DIY battery pack assembly due to its reliability and efficiency.

Advantages of Lipo-Battery Welding

Spot welding has numerous distinct advantages. First off, it offers low-resistance connections, which are essential for increasing the effectiveness and performance of packs. Another major advantage is precision, which allows welders to accurately regulate the heat delivered and lower the danger of cell damage.

The lifespan of the battery pack is further ensured by the fact that the connections produced are robust and resistant to a variety of external factors. Due to these benefits, experts, and enthusiasts who work on high-performance packs, where dependability and low resistance are crucial for maximum operation and safety, prefer lipo-battery welding.

Alternatives to Lipo-Battery Welding

While this is a popular choice for connecting cells, several alternatives exist, each with its own set of advantages and disadvantages.

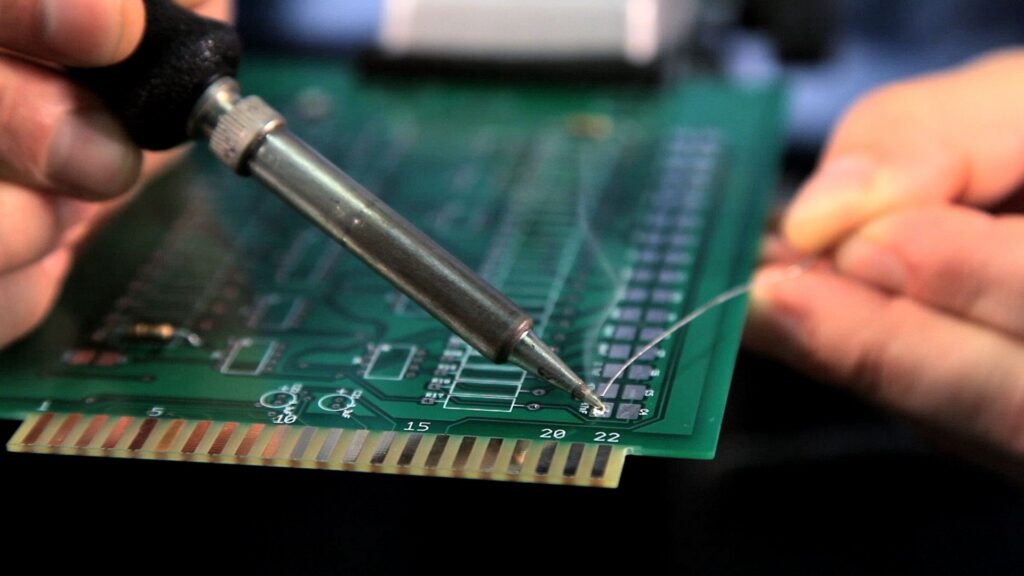

- Soldering: Soldering involves melting solder onto cell terminals. It’s a widely used DIY method due to its simplicity, but it may result in higher resistance and less robust connections compared to welding.

- Spot-Welding Pen: This portable tool offers convenience but might lack the precision of a dedicated spot welder. It’s a more budget-friendly option, making it suitable for hobbyists.

- Adhesive Strips: Some opt for conductive adhesive strips, which are easy to apply. However, these strips often have higher resistance and are better suited for temporary solutions or prototyping.

When selecting an alternative, consider factors like your skill level, project requirements, and budget. While these alternatives may work for specific applications, they may not provide the same level of reliability and low resistance that welding offers, especially for high-performance packs.

Choosing the Right Method

Choosing the right method for connecting cells is a crucial decision in any project. Your choice should be guided by factors such as your level of expertise, the specific application, and your budget.

For professionals and those seeking top-tier performance, it stands out as the preferred method. Its precision, low resistance, and durability make it ideal for high-performance packs.

On the other hand, if you’re a DIY enthusiast looking for a more accessible option, soldering or spot-welding pens can be suitable alternatives. These methods are easier to learn and use without specialized equipment.

Lastly, adhesive strips may be considered for temporary solutions or prototypes but are generally not recommended for long-term projects due to potential issues with resistance and durability.

Opting for DIY welding? Here are some DIY welding safety practices that you should be aware of if you want to do welding yourself.

Conclusion

In conclusion, lipo-battery welding remains the gold standard for creating reliable, low-resistance connections in packs. However, alternatives like soldering and spot-welding pens can be suitable for certain situations.

The choice ultimately depends on your project’s requirements, budget, and your level of expertise. Whatever method you choose, prioritize safety and quality to ensure your pack performs optimally and safely.