6 Things You need to know about PCB box build assembly

The PCB box build assembly is an essential part of various electromechanical processes. It’s crucial to everyone who’s trying to produce some type of electronic device. If you’re in a need of this service but you’re not sure where to start, we’re here to help!

Planning a box build assembly project is nothing overly complicated. As long as you manage to find a reliable manufacturing company, everything will certainly go as planned. Still, there’s a couple of things you should consider before starting the project, and here are some of them.

1. The dimensions of the unit come first.

The size and weight of the unit is something you should consider right off the bat. It will allow you to plan the entire project much more efficiently as it will affect the costs of manufacturing, shipping, handling, and installation. The first thing you should do is to design a draft that deals with the unit’s most basic properties. These specs are the first thing the manufacturing company will inquire about. Take your time and consider the specifics of your project. Consult with an industry professional who can help you find the most cost-effective solution without losing on quality.

Keep in mind that everything depends on your specific needs and goals. You should consider all the available options before making your final choice. The quality of the final product should be your primary concern. So, don’t hesitate to research every possible solution before contacting your chosen manufacturer.

2. Bill of materials (BOM) is essential for box build assembly projects.

The second thing you should consider while planning a box build assembly project is the BOM. This document contains crucial information that will help your manufacturer to bring your idea to life. In short, it’s a list of key requirements and components that represent the outline of your design. Try to give as much detail as possible. The more you communicate with the manufacturer, the better the end result will be. Of course, the Bill of Materials doesn’t have to include every single detail of your project, but even if you choose to go with that route, you wouldn’t be making a mistake. Your manufacturer is certainly going to have some additional questions, so keep your engineers near you and prepare to answer all of their inquiries as promptly as you can.

3. The design matters.

Visualizing the design is probably the most significant part of the entire project. The most effective way you can do this is via 3D CAD modeling technology. These designs can serve as an excellent way for your manufacturer to create the cutting lists.

Of course, if you’re not all that familiar with the technologies used for 3D modeling, we suggest you outsource an expert to help you. Whatever you do, make sure to provide the design to your manufacturer, as they’ll be able to convert it into build instructions easily.

Even though you’ll have to provide the design yourself, don’t hesitate to consult with the manufacturer to analyze the potential alternatives if necessary. Your EMS providers can be your best friends and advisors during the process, so keep the communication open and be prepared to answer many of their questions.

4. Make sure to choose the right EMS provider.

Now, the quality of the entire assembly will mainly depend on your choice of manufacturer. Finding the right company can sometimes be quite difficult, especially if you lack experience in the industry. The most popular market for quality EMS providers is certainly China, but there’s nothing wrong with looking into your “local” options first.

As there’s not much info on these types of companies online (besides what they say about themselves), we suggest you seek help from an industry professional. If you have someone like that in your contacts list, that’s great, but if you don’t, your best shot is to contact different companies and determine which one fits your needs by yourself. PCB box build assembly services such as Uetpcb should be responsible, transparent, responsive, and experienced to be a good pick for your project. Lastly, sometimes you’ll just “click” with a certain manufacturer, so listen to your gut feeling and you’ll certainly be successful.

5. Prototyping is always a good idea.

Although sampling and prototyping isn’t a necessary part of PCB box build assembly projects, it’s still a great way to provide detailed information to your manufacturer. Of course, creating a functional prototype isn’t an easy task. In most cases, you’ll need to employ a couple of engineers to help you with building it. However, it’s usually worth the money since it helps the manufacturer create your final product more efficiently.

Overall, if your project is a bit more complex (it has a large number of components), making a prototype can ensure better results in the end.

6. Testing, testing, testing!

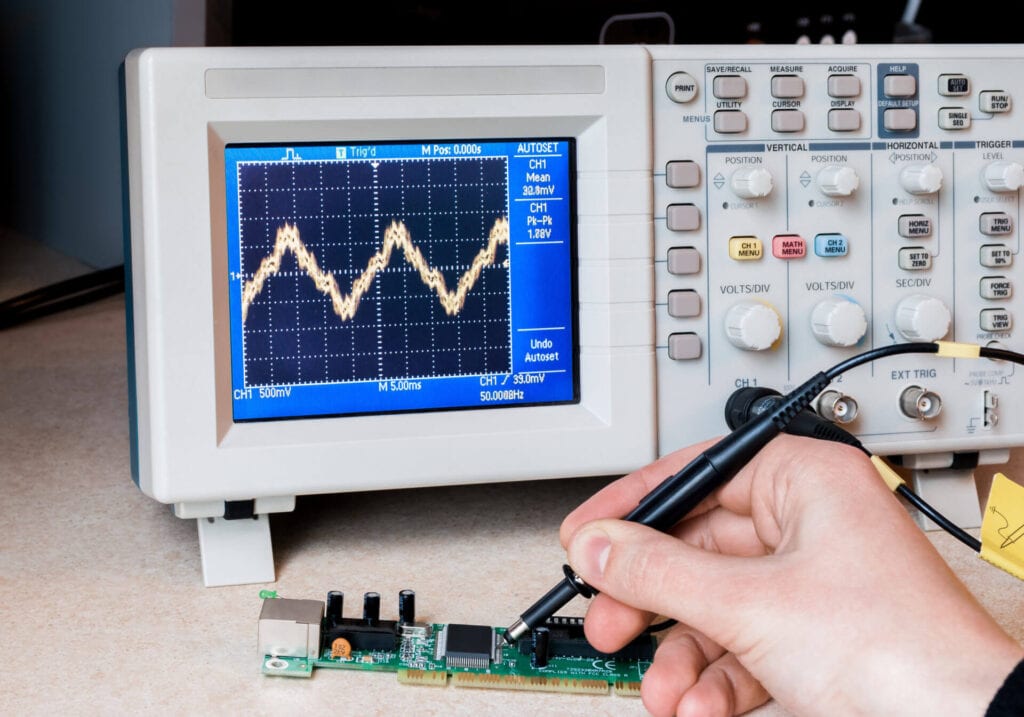

Finally, once everything is done, you have to consider testing and inspections. You must ensure everything looks and works as you imagined. Even more importantly, testing will determine whether the product is safe for use or not. Your EMS provider can help you choose the best testing tactics and methods as they have enough experience to make an educated suggestion.

Make sure to do some research on various types of tests and inspections that are the industry standard for your type of product. Naturally, whatever you choose to do, you can’t go without the standard electrical safety tests. These are not enough for complete quality assurance, but they’re a good place to start. So, make sure to discuss these with your provider prior to shipment.

The bottom line.

All in all, PCB box build assembly projects require some planning and preparation to be done properly. Your EMS provider should be able to guide you through the process so you don’t have to worry. With that being said, choosing a reliable company to help you with the project is of the utmost importance. Make sure to interview a couple of them until you find something that fits your goals, needs, and your budget.