Hydraulic hoses play a crucial role in the functioning of many industrial machines and equipment. From construction and agriculture to manufacturing and transportation, they transmit pressurized fluids to power various mechanical operations. While we may often overlook the importance of these unassuming tubes, the science behind their manufacturing is both fascinating and essential. In this article, we will dive into the world of hydraulic hose materials and uncover the secrets behind their construction.

The manufacturing process of hydraulic hoses involves selecting the right materials to ensure durability, flexibility, and resistance to extreme pressure and temperature conditions. Engineers and scientists continually strive to develop innovative materials that can withstand the demanding environments in which hydraulic systems operate.

Hydraulic Hose Manufacturing Materials

One of the primary materials used in hydraulic hose manufacturing is rubber. Natural or synthetic rubber compounds are chosen for their excellent flexibility and ability to handle high pressures. Rubber ones are made by mixing rubber with various additives and curing agents to enhance their strength and resistance to abrasion. Additionally, the incorporation of reinforcement layers, such as braided or spiraled high-tensile steel wires, further enhances the structural integrity of the hoses.

Another material commonly used is thermoplastics. These materials possess exceptional resistance to chemicals, abrasion, and high temperatures. Thermoplastic hoses offer advantages such as light weight, flexibility, and compactness, making them ideal for applications where space is limited. Additionally, they can withstand a wide range of pressures and are often used in high-pressure hydraulic systems.

Properties of Different Materials

Understanding the properties of different materials is crucial in selecting the right one for a specific application. For instance, in environments with high heat and intense flames, those made from flame-resistant materials are essential to prevent accidents and ensure worker safety. Similarly, in industries dealing with corrosive chemicals, those with excellent chemical resistance properties are a must.

The science behind hydraulic hose manufacturing also involves extensive testing to ensure the quality and performance of the final product. These tests involve subjecting the hoses to extreme pressures, temperature cycles, and rigorous flexing to simulate real-world conditions. Only those that pass these stringent tests are deemed suitable for use in critical applications.

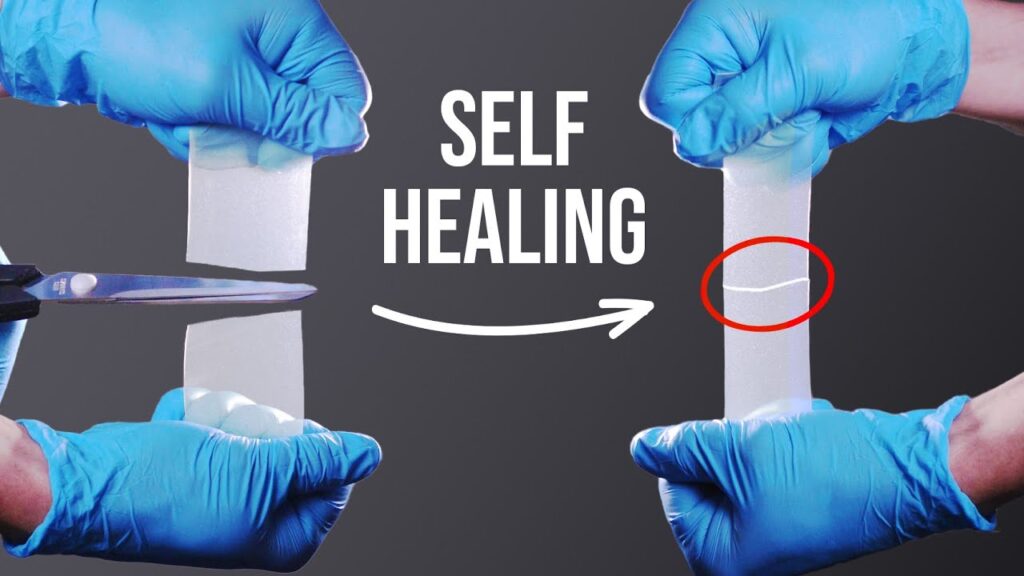

Self-Healing Materials

In recent years, advancements in materials science have paved the way for the development of innovative hose materials. For example, nanotechnology has enabled the creation of self-healing materials that can automatically repair small punctures or cuts in the hoses. This breakthrough has significantly increased the lifespan of hydraulic hoses, reducing maintenance costs and downtime.

Furthermore, the quest for more environmentally friendly solutions has led to the development of bio-based hydraulic hoses. They are made from renewable resources and have a reduced carbon footprint compared to traditional materials. By adopting such eco-friendly alternatives, industries can contribute to sustainability efforts while maintaining the efficiency and reliability of their hydraulic systems.

As we explore the science behind hydraulic hose manufacturing, it becomes evident that these seemingly simple tubes are the result of extensive research, engineering, and innovation. The careful selection of materials, the incorporation of reinforcement layers, and the rigorous testing processes all contribute to the creation of durable and high-performance hoses.

Conclusion

Next time you encounter a hydraulic system in action, take a moment to appreciate the complex science that goes into the manufacturing of the hoses that power it. From rubber compounds to thermoplastics and cutting-edge materials, hydraulic hose manufacturers continue to push the boundaries of what is possible, ensuring the smooth functioning of countless industries worldwide.