Biggest Design Mistakes to Avoid in Photo Etching

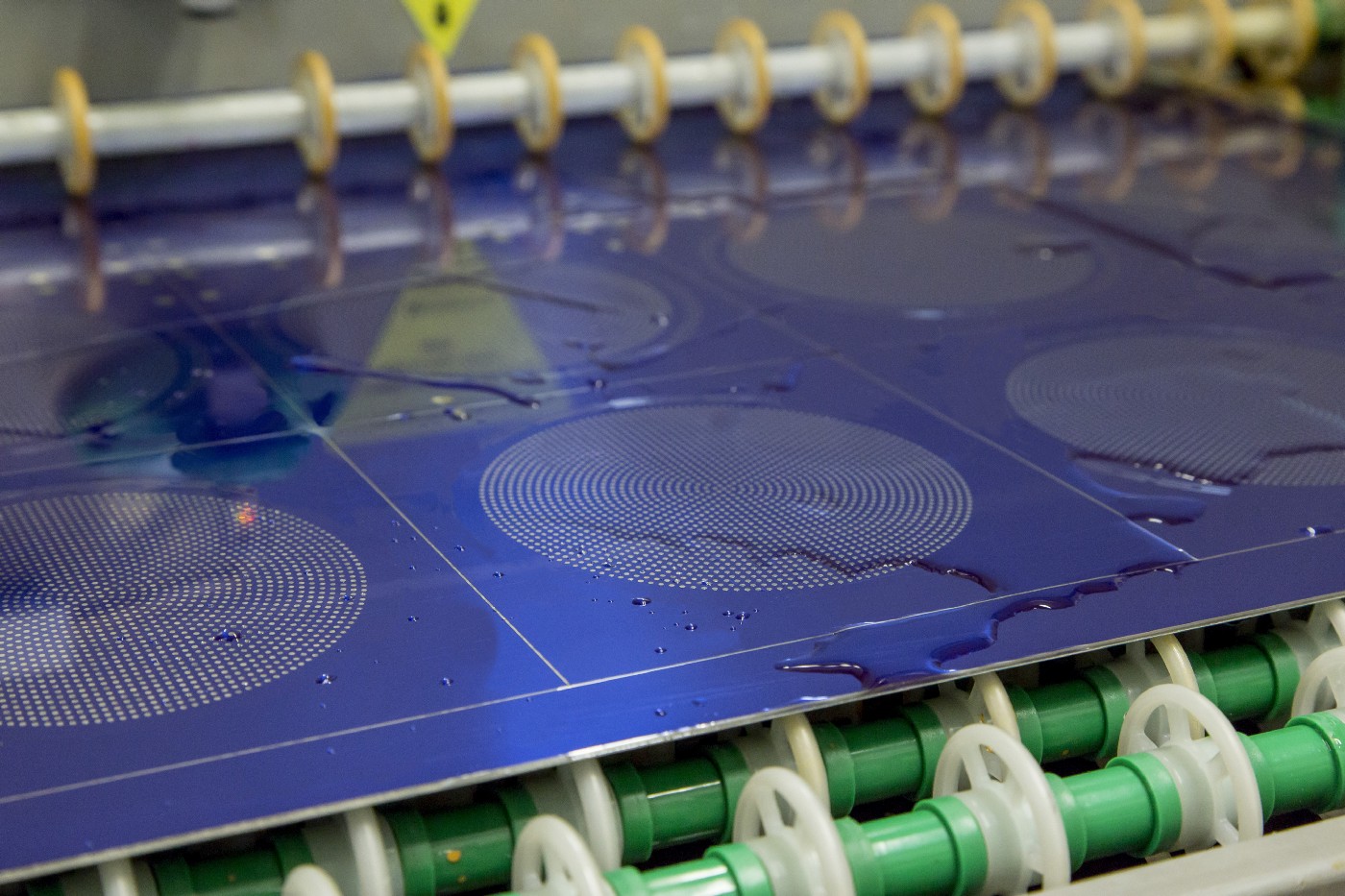

Photo etching has some other terms that people commonly use such as photo-chemical etching (PCE) and photo-chemical machining (PCM). However, they all represent the use of phot-reactive resist to fabricate precision metal parts that are based on some particular dimensions.

In general, if you never heard of this process, you should know that it is quite similar to the printing process. This is because it reflects part dimensions on the photo-resist coated metal. This metal is developed and etched, so the outcome can be desired.

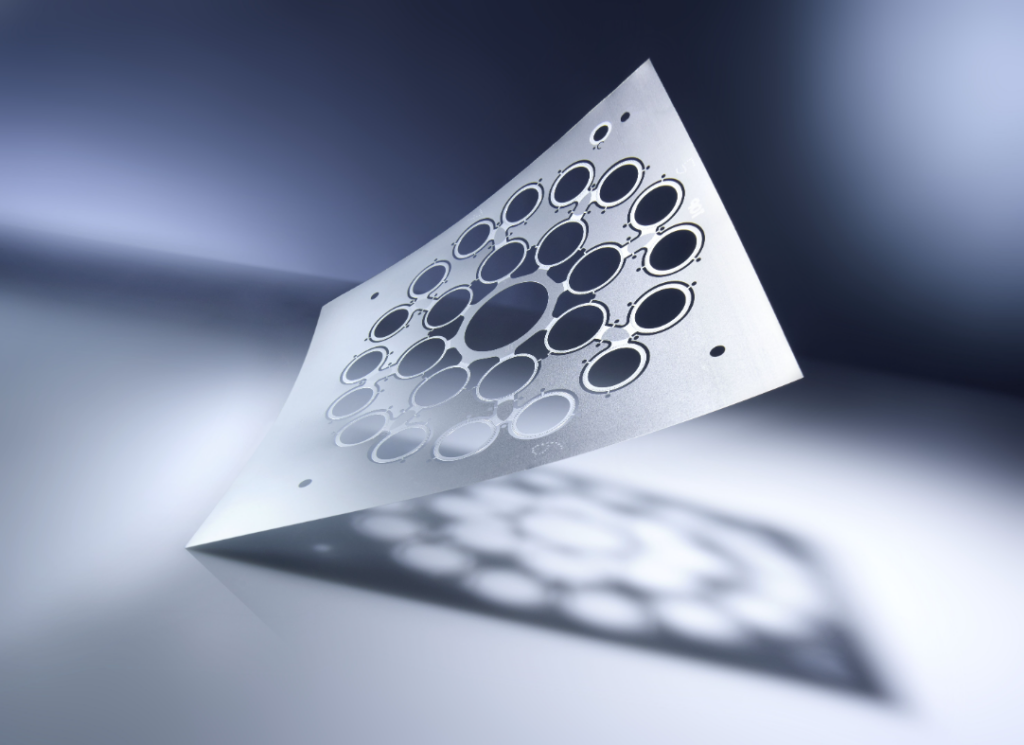

It is worth mentioning that the etching process is producing intricate pieces with tolerances as low as ± .01 mm. This is very important since this is not possible to achieve with some other methods including laser cutting, stamping, punching, water-jet cutting, or anything else.

Photo etching benefits

There is a wide range of benefits that photo etching is coming with. By using digital photo tooling, they are able to produce as well as change prototypes very fast and effectively. At the same time, the low cost is ensured as well as the risk-free design optimization. In the cases where component integrity is critical, only the etching process can be suitable metal machining technology that will not affect and modify the metal properties.

Additionally, in this process, there is no heat or any type of mechanical force that has been used which refers to the fact that all components are free from any form of burrs and stresses. It is interesting that compared to any other method, the etching process is the most economical option that enables producing custom and unique pieces with completely complex designs. Best of all is that the overall final cost does not increase with design complexity.

If you are intrigued to find out whether you can photo-etched your company logos, serial numbers, or something else into the surface of the etching parts, they will not come with an additional cost. Your options are truly unlimited when it comes to this procedure.

Let’s get a summarized picture of all advantages of this etching process. Primarily, it does not include any type of mechanical stress. Also, it dissolves the metal that is unwanted with a special chemical reaction. This means that burring, shearing, and ablative deformation are avoidable and are linked to some other machining procedures. Next, it is highly important to notice that the etching process improves the precision to the fullest. This literally means that chemical etching can be used with some materials that are thin .0003 inches.

Despite that, this process is enabling high part quantities which means that large parts volumes can be effectively put into production that leading to a higher flexibility level. It is worth mentioning that the process also supports greater part complexity. As we said, all complex dimensions of metal components can be generated. The process can even be built score lines and all parts will be folded perfectly. Finally, as we mentioned above, with this etching process you are getting lower production costs.

What are the biggest design mistakes that you should avoid in the photo etching process?

After you have decided that you want to use the process of photo etching for your part design, you need to be aware of some things and the common mistakes that you should avoid. Let’s get to the point and find out some of the most important things you need to consider as an engineer.

You should be careful when choosing the type of metal

Photo etching is properly suitable for various types of metals including steel, aluminum, copper metal, etc. Since the metal is etched and there is no hard work with stamping included, as well as the heat produced by laser cut, you can expect a successful outcome with stress-free features. However, you should know that stamping is not the best option for soft, hard, or even brittle metal types. Additionally, working on aluminum is difficult for laser cutting because of its reflective features that can make damage machine components.

When it comes to the stainless steel etching, you should know that this is a very popular option since it comes with high-quality features such as strength and corrosive resistance, and it is very affordable. These features are considered by every industry where chemicals, fluids, and temperature fluctuations are exposed.

The copper metal type is a softer one that allows the etching process to be faster. Since it comes with large production volumes, this etching process can be a cost advantage compared to other processes. Finally, you should know that the aluminum etching process is currently very famous in the automotive industry. They come at an affordable cost and a high strength-to-weight ratio.

You must consider Metal Thickness

In general, you should be familiar with the fact that etched parts with the chemical etching process can range in terms of thickness from 002″ to .060″. Additionally, the thicker the metal is, then you should know the process of etching will be longer. Having this in mind, it would be a very good idea to select the lowest thickness of metal possible.

This will truly save you both money and time. Additionally, if you make a decision of this kind, thinner materials will generate more parts of the sheet because the lower tolerance is going to be maintained. In case a part needs a greater metal thickness, you should use a smaller sheet size and attain lower tolerance. However, this will increase the cost.

Pay attention to Dimensional Tolerances

Finally, you should need to consider dimensional tolerances as an important part of the etching process. For all chemical metal etching successful outcomes, it is necessary that engineers specify the proper dimensional tolerance from the beginning of the process. If you do not pay attention to this and you do not get a clear picture of the etching capabilities, you are risking design iterations and tooling revisions.

Additionally, it is required for the part to include the lowest tolerance in order to properly function. However, you should remember that this can increase the cost unnecessarily. When you are being more generous with the tolerances, you are going to control the costs and at the same time yield more parts.

Conclusion

After reading the article and gathering all the necessary information about the photo etching process, you can contact the reliable and professional metaletching.com company that can offer a high-quality services for complex designs.