Research shows that when it comes to manufacturing, most workers experience upper extremity injuries. Injuries to the hand or fingers most often occur, and this is because of the nature of their job. This is especially prevalent in the glazing industry. It takes very little for workers to injure themselves when working with uneven edges.

The solution to this problem is constant care for the health of employees by minimizing the possibility of injury to employees. In order for this to be realized, the industry must provide its workers with the necessary equipment and conditions for safe work. Manufacturers should also take the time to train their employees to use glass safely, etc.

There are several other ways in which glass manufacturers can increase the safety of employees at work. To find out all the ways you can read them below.

Safe environment

Of course, we mean the environment of the company in which the employees work. The most important thing is to establish general safety. This is achieved by ensuring the safety of workers in production conditions. Also, such a safe environment cannot be implemented without the responsibility of the workers. They must respect the security policy and be sanctioned otherwise because they endanger everyone else.

This applies not only to workers who come into contact with the products but also to other staff such as management and the visitor. Together, they contribute to or diminish the safety of the environment in which they are located. So, in the beginning, it is primarily to develop responsibility in employees. Manufacturers should have specific disciplinary measures in this case, because that ultimately benefits everyone who works in this industry.

Experts conducting analyzes in this business sector say that an individual interview should be conducted with each employee who does not comply with these measures. Sanctioning should be carried out by levels, from lower to higher by superiors determining the consequences of non-compliance and protocol. Employees should receive one warning, followed by suspension or dismissal.

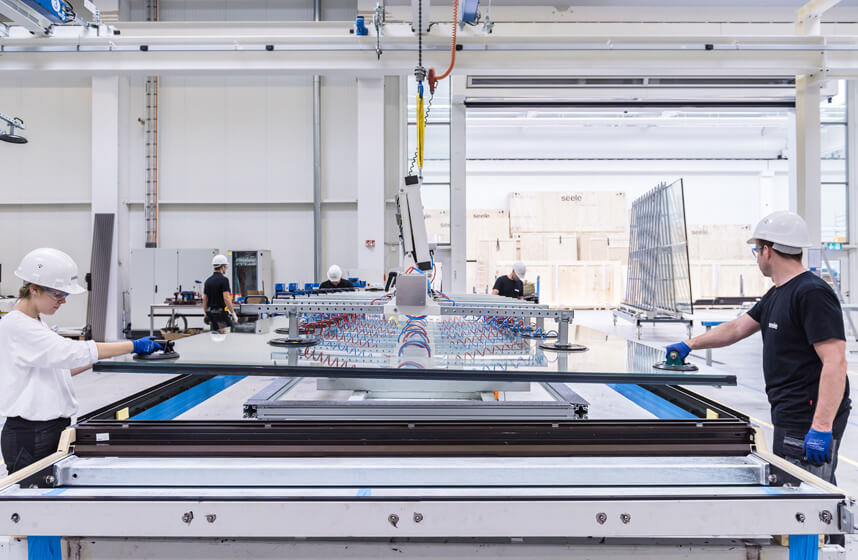

Protective gear

Employees who are in daily contact with glass should have personal protective equipment. Without it, they should not start their working day. The equipment usually consists of protective gloves and specially made goggles, but it is not the same for all workers. It adapts to the tasks given to workers.

However, the main equipment also includes helmets, shields, protective jackets and boots. Manufacturers should provide all this to their workers so that they can change the equipment depending on the type of work they perform. In this way, all parts of the body are protected, especially the upper part, which is the most sensitive.

However, the type of equipment also depends on the level of danger to which workers are exposed. So you can find in the production upgrade all the previously listed items of equipment. For example, when it comes to processing annealed glass, workers will use special glasses with side shields and special footwear.

Working with glass without danger

Although today almost everything is subject to automation, workers still have to come into contact with glass when moving in production, etc. As you all know, it is not a naive job at all and it is very dangerous for everyone. The reason is the high level of fragility and density of glass. Although at first glance glass may seem like a very light product that is not difficult to handle, you are wrong.

Therefore, superiors should provide the conditions in which these products will be moved. This applies to both relocation processes – loading and unloading. It is important to establish a clean environment in which there is a restriction of movement for all those who are not employed in this sector. That way, the workers will not be afraid of obstacles. It would be good to use lights as a warning sign in this area during these precautionary measures, it will be clearer for all employees.

Employee education

As we have already mentioned, manufacturers should make sure that people how work for them have the necessary knowledge when it comes to handling glass, machines, etc. That means training them. Everyone should know at the end of the training to safely raise and hold the glass, as well as to get away in case of falling glass. This is very interesting, but most people would catch the glass when it falls. It’s our natural reaction that we have from birth – we catch things falling.

However, doing this in the glazing industry is not at all smart, but it can lead to a fatal outcome. So, when the glass falls, it should be pointed out to the employees to exclusively move to the side to safety. Employees should also be provided with training, and when it comes to production tools, they must know how to manage them properly.

In addition to all the above, education also refers to the theoretical part. It is knowledge of glass, its characteristics, load-bearing capacity, weight, types, etc. It is important that staff know the material they are working with

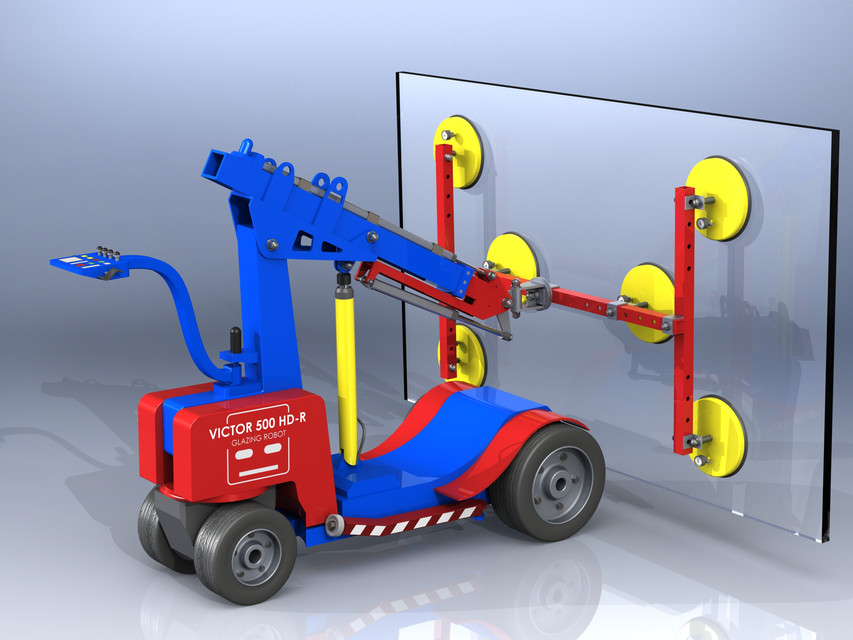

Lifting robots

We must not forget the machines that are an integral part of this industry. If the superior has fulfilled the previous condition – education, they must know how to properly operate the machines. This way, they will be spared the painstaking work that machines will do instead. Of course, in addition to good management, they must be properly and regularly maintained.

Experts say that the operation of the machine contributes to better safety. In this way, they come into less contact with the sharp edges of the glass when it comes to cutting, breaking, etc. However, it turned out that the best combination of machines and people. On this website, you can find more details about glass lifting robots.

Conclusion:

As you can read, there are many ways workers can spend their time safely at work. It is very important that glass manufacturers take these steps. However, this does not only mean a lower risk of employee injuries and glass breakage. This kind of work has a positive impact on customers who take seriously the company that cares about their employees as well as the products.